About us

Shandong Boxing County Ruixinlong New Materials Co., Ltd. was established in October 2013 and is located in Dianzi Town, Boxing County, Shandong Province, China. The company has a superior geographical location and convenient transportation, which makes product transportation and logistics management very convenient. The company specializes in the production of metal materials such as color-coated steel plates, with an annual production capacity of 500,000 tons. The total investment in the project is US$50 million, of which US$4 million is invested in environmental protection, reflecting the company's firm commitment to green development and sustainable development. The company has an advanced color coating workshop and two efficient continuous color coating steel plate production lines, using advanced technical equipment and strict production processes to ensure that all products meet international standards. The company has 160 professional and technical personnel, including 52 technical experts and 18 managers, with strong technical research and development and production management capabilities. Shandong Boxing County Ruixinlong New Materials Co., Ltd. has a wide range of products, including color-coated steel plates, galvanized plates, composite plates, rock wool plates, etc. In addition, we also provide sales services for kitchen equipment, knitted products and chemical products, and have the ability to package and sell coatings and water-based paints. We are committed to providing high-quality environmentally friendly products that meet industry needs to our global customers, especially partners in the African market.

development history

Adhering to the corporate spirit of "being a person, building a business, and serving the country with the will of steel", Ruixinlong actively promotes the high-end transformation of steel intelligent manufacturing, and focuses on building a permanent benchmark enterprise in the industry based on the ideas of "quality, high-end, green, and ecology", contributing the wisdom and strength of Ruixinlong to the development of the steel industry!

Factory reconstruction

The color coating and galvanizing workshops were upgraded and renovated, and a new branch was built, with annual production capacity increased to 500,000 tons and annual sales increased to US$370 million. The total investment in the project reached US$50 million, and the staff size was expanded to 400 people, including 160 professional and technical personnel, including 52 technical experts and 18 management personnel. The company has a number of invention patents and technology patents.

Expand production scale

The company added two continuous color-coated steel plate production lines with an annual production capacity of 180,000 tons; at the same time, it added two galvanized production lines with an annual production capacity of 200,000 tons. The total investment in the project reached US$30 million.

Company established

The company is located in Dianzi Town, Boxing County. Initially, it was a color-coating workshop with about 50 employees and an annual sales revenue of 29 million USD.

All for the customer's peace of mind, confidence, and honor.

Research and Innovation

Ruixinlong boasts a research and development team of over 100 professionals. Its testing and inspection center is CNAS-certified, and its corporate technology center has been recognized as a Shandong Provincial Enterprise Technology Center. The company collaborates with prestigious institutions such as Shandong University, University of Science and Technology Beijing, and the Iron and Steel Research Institute on industry-academia-research projects.

In recent years, Ruixinlong has completed more than 100 R&D projects, including 36 Shandong Provincial Science and Technology Innovation Projects. The company has obtained 16 invention patents, 114 utility model patents, and 13 software copyrights.

36

Provincial level technological innovation projects

4

City level R&D platform

CNAS accredited laboratory

The Ruixinlong Laboratory's CNAS certification covers the testing of metal materials and related products, with a scope encompassing 14 performance indicators, including mechanical properties, Vickers hardness, and chemical composition.

CNAS is the English abbreviation for the China National Accreditation Service for Conformity Assessment. Approved and authorized by the China National Accreditation Regulatory Commission (CNARC), it is currently the only organization in China qualified to issue national accreditation for laboratories.

Once a laboratory obtains CNAS certification, its inspection reports gain international recognition.

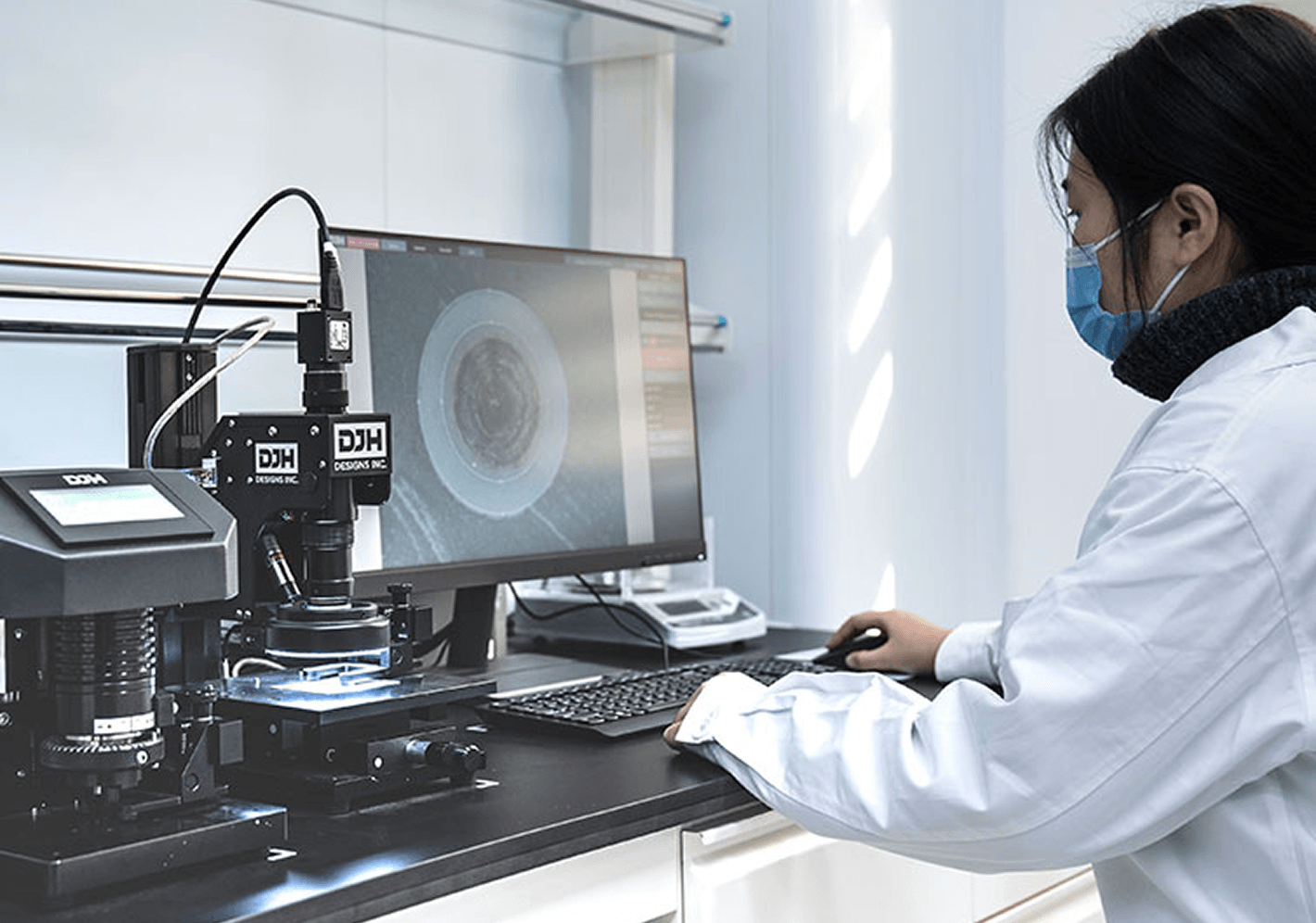

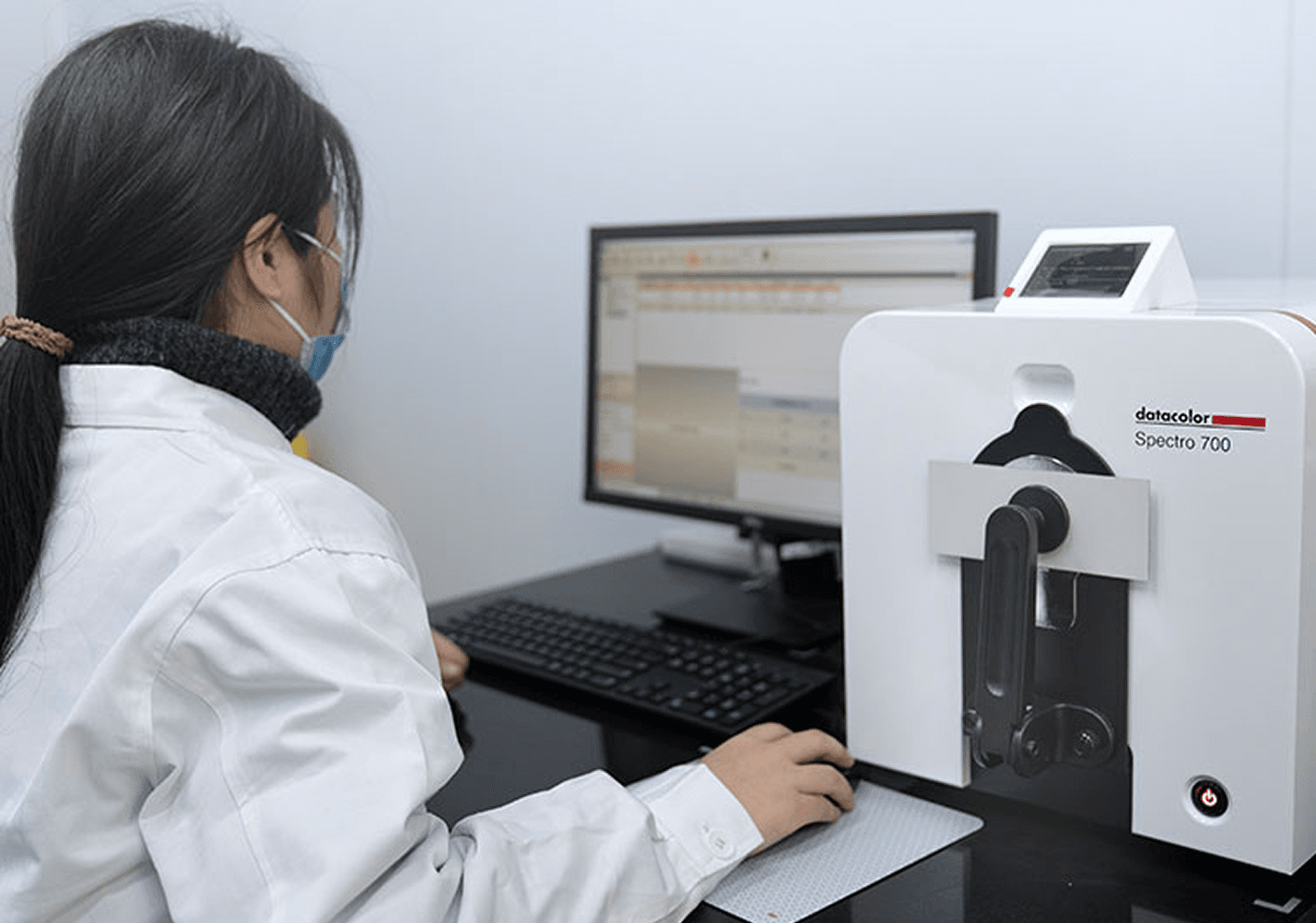

Color Picture Laboratory

The Color Coating Laboratory is staffed with a team of professional technical personnel and equipped with advanced R&D facilities, including internationally leading instruments such as the DJH Coating Thickness Gauge, Datacolor Chroma Meter, Q-LAB UV Accelerated Weathering Tester, and Q-FOG Cyclic Corrosion Salt Spray Chamber. These state-of-the-art equipment enable comprehensive performance testing for color-coated products.

The DJH Coating Thickness Gauge is currently the world's most precise coating thickness measurement system, capable of accurately determining the thickness of each coating layer. The Datacolor Chroma Meter performs stringent color difference testing to ensure consistent color across different production batches, thereby guaranteeing product appearance quality. The Q-LAB UV Accelerated Weathering Tester conducts periodic accelerated durability tests to evaluate the weather resistance of color-coated panels and ensure product performance. The Q-FOG Cyclic Corrosion Salt Spray Chamber performs accelerated corrosion resistance tests to assess the long-term anti-corrosion properties of the coatings.

Additionally, the laboratory conducts various test items including the Erichsen Cupping Test, Impact Resistance Test, T-Bend Test, and Pencil Hardness Test. These tests examine critical performance indicators of the coatings during processing and application. Through rigorous quality inspection and control, the laboratory ensures optimal matching of various properties in each production batch, thereby meeting practical processing and application requirements.

TPM management

TPM (Total Productive Maintenance), translated as comprehensive production management, is a management model aimed at pursuing the maximum production efficiency. The JIPM-TPM Excellence Award in Japan is known as the "Nobel Prize in Manufacturing". Ruixinlong successfully challenged the JIPM TPM Excellence Award for Class B factories in 2022, marking another step towards becoming a world-class manufacturing enterprise.